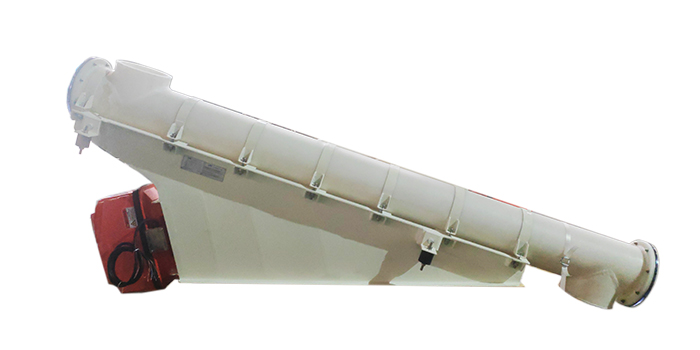

En la industria alimentaria altamente competitiva de hoy, lograr un transporte de materiales eficiente, preciso y seguro se ha convertido en un problema urgente que muchas empresas alimentarias deben resolver. Alimentador vibratorio electromagnético VRV Aporta una nueva solución a la producción de alimentos con su excelente rendimiento y diseño innovador.

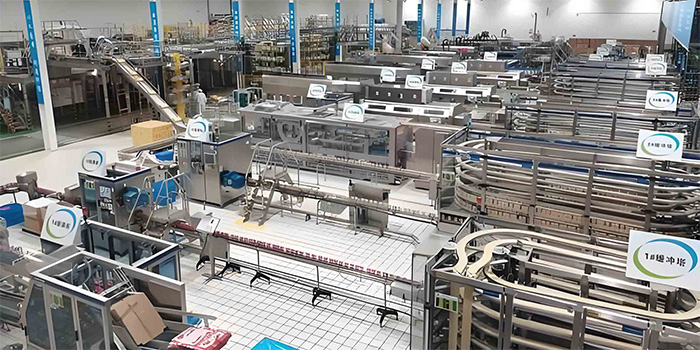

En la línea de producción de alimentos, el transporte preciso de materiales es crucial para garantizar la calidad del producto y la eficiencia de la producción. Ya se trate de granos granulados, caramelos, condimentos en polvo y leche en polvo, el alimentador vibratorio electromagnético VRV puede procesarlos con facilidad. Su exclusiva tecnología de vibración electromagnética permite una alimentación uniforme y estable de materiales, con un margen de error mínimo. Tomemos como ejemplo la producción de caramelos. Al envasar caramelos de diferentes formas y tamaños, los equipos de alimentación tradicionales pueden experimentar problemas como la acumulación de caramelos y una velocidad de transporte inestable, lo que resulta en una baja eficiencia de envasado y cantidades de embalaje inconsistentes. Sin embargo, el alimentador vibratorio electromagnético VRV puede controlar con precisión el ritmo de transporte de cada caramelo según los parámetros preestablecidos. El error del volumen de transporte por minuto no supera el ±1%, lo que garantiza una cantidad precisa de caramelos en cada paquete y mejora considerablemente la estandarización de los productos.

En el proceso de producción de alimentos, la higiene y la seguridad son de suma importancia. VRV es plenamente consciente de ello y ha considerado plenamente los requisitos especiales de la industria alimentaria al diseñar el alimentador vibratorio electromagnético. El equipo está fabricado en acero inoxidable de grado alimenticio, con una superficie lisa y sin costuras. No solo es resistente a la corrosión, sino que también previene eficazmente los residuos de material y el crecimiento bacteriano. Además, su diseño estructural facilita el desmontaje y la limpieza, reduciendo los pasos engorrosos del proceso de limpieza y los costes de mano de obra y tiempo. En la producción láctea, una vez finalizada la producción diaria, el personal puede desmontar rápidamente cada pieza del alimentador con operaciones sencillas y utilizar un producto de limpieza especial para una limpieza a fondo, garantizando así que el equipo esté limpio e higiénico para el siguiente uso y cumpla con las estrictas normas de seguridad alimentaria.

Además de la precisión y la higiene, el alimentador vibratorio electromagnético VRV también ofrece un excelente rendimiento en términos de ahorro de energía y protección del medio ambiente. El equipo utiliza un sistema avanzado. sistema de accionamiento electromagnético Esto reduce el consumo de energía en más de un 30 % en comparación con los equipos de alimentación mecánicos tradicionales. Durante su funcionamiento, el alimentador vibratorio electromagnético genera muy poco ruido, lo que no interfiere con el entorno de trabajo del taller y crea un ambiente de trabajo tranquilo y confortable para los empleados. Esto no solo se ajusta al concepto de producción ecológica de las empresas modernas, sino que también supone un importante ahorro en costes operativos. Tomemos como ejemplo una gran fábrica de procesamiento de alimentos. Tras utilizar el alimentador vibratorio electromagnético VRV, el gasto anual en la factura eléctrica se ha reducido en cientos de miles de yuanes y, al mismo tiempo, se evitan posibles consecuencias ambientales derivadas de la contaminación acústica.

Además, el alimentador vibratorio electromagnético VRV también ofrece un alto grado de inteligencia y flexibilidad. Al integrarse perfectamente con el sistema de producción automatizado existente de la empresa, puede ajustar la velocidad y el volumen de alimentación en tiempo real según las necesidades de producción. Al producir diferentes tipos de alimentos, con solo introducir los parámetros correspondientes en el sistema de control, el equipo puede cambiar rápidamente al modo de trabajo sin necesidad de complicados ajustes mecánicos. Este diseño inteligente mejora considerablemente la eficiencia de la producción y reduce el tiempo de inactividad causado por el ajuste del equipo, generando mayores beneficios económicos para las empresas.

Con el continuo desarrollo de la industria alimentaria, los requisitos de los equipos de producción son cada vez mayores. El alimentador vibratorio electromagnético VRV, con su preciso control de alimentación, estrictos estándares de higiene, excelente ahorro de energía y un alto nivel de inteligencia, se ha convertido en la opción ideal para que las empresas alimentarias mejoren su competitividad. Se cree que, en el futuro, VRV seguirá impulsando la innovación, aportando equipos y soluciones de producción más avanzados a la industria alimentaria y contribuyendo a su avance hacia una etapa de desarrollo de mayor calidad.

llamanos :

correo electrónico : sales@vrvibratory.com red ipv6 compatible

red ipv6 compatible